General information about KLEEcoils

What is a KLEEcoil?

KLEEcoils are metal threaded bushings with internal or external thread, which are slightly conical at one end and have slots or side holes. The bushings are self-tapping and can therefore be screwed into bores without prior thread cutting. Properly installed, the bushings withstand heavy tensile loads and also withstand vibrations of any kind. The internal thread is precise and very durable.

Where are KLEEcoils used?

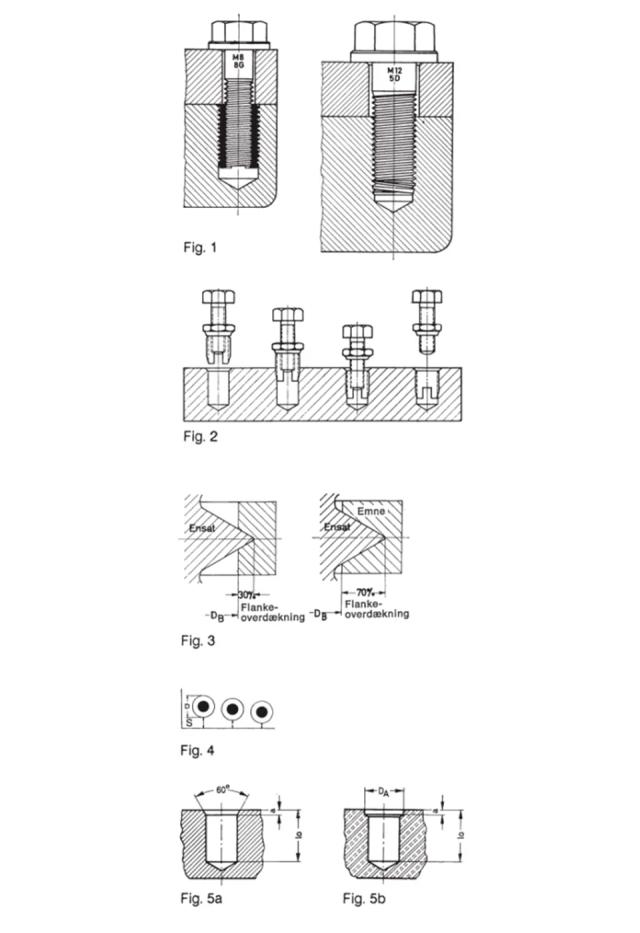

KLEEcoils are used in light metal alloys, cast iron, plastics, wood and fiber materials. You can save material by using smaller screws with a higher load (see fig. 1). KLEEcoils are also suitable for repair of worn threads. The worn thread is drilled away and replaced by a KLEEcoil. This means that you can continue to use the same screw diameter. You also get a better and more durable thread.

How to mount KLEEcoils?

If you only need to mount a single or a few KLEEcoils, it can be done as shown in fig. 2. In serial production tools are used.

Easy and trouble-free installation is achieved by following the instructions below:

1) KLEEcoil type is chosen according to material and hardness.

2) The diameter of the hole is determined on the basis of the tables used for the individual types. The concept of 'flank coverage' is defined in fig. 3.

3) Minimum wall thickness "S" depends on the elasticity of the material: Plastics 0.25 D to 0.90 D

Light metal alloys 0.25 D to 0.60 D

Cast iron 0.30 D to 0.50 D

D is the outside diameter of the KLEEcoil. See fig. 4.

4) The KLEEcoil should be recessed as shown in fig. 5a or fig. 5b.

Metallic materials and plastics a = 1 to 1.5 times increase of with low to medium hardness: external thread (Fig. 5a)

Hard and brittle plastics: DA = D + 0.2 to 0.4 mm. a = 1 to 1.5 times pitch of external thread (Fig. 5b)

Quality

The production of KLEEcoils take place in Germany according to DIN EN ISO 9001 and ISO/TS 16949:2002 and ISO 14001:2004. KLEEcoils are continuously tested and checked during and after production.

BRD KLEE A/S is certified according to ISO 9001:2015 by Norske Veritas. Should KLEEcoils not live up to your expectations even if they are used according to the recommendations then contact BRD. KLEE immediately.

Types of coils

There are different types of KLEEcoils.

Kleecoil Self-cutting types

KLEEcoils self-cutting types are threaded bushings for many types of material. Can also be used to repair worn/damaged threads.

KLEEcoil reduction type

KLEEcoil reduction type are replacement bushings and reduction bushings for reducing thread size.

Type M and MO.

KLEEcoil Self-locking types

KLEEcoil Self-locking types are self locking expanision bushes for different types of plastic. Manufactured in brass. Available with and without flange.

KLEEcoil for heat/ultrasonic

KLEEcoil for heat/ultrasonic

KLEEcoil Threaded bushing for heat and ultrasound

KLEEcoil Threaded pins for heat and ultrasound

KLEEcoil-Mubux special bushings for pressing in type 850/852 and 856/857. KLEEcoil SonicLok Threaded bushing for heat and ultrasonic assembly type 853-855; type 858/859; type 860-862; type 863/864 and type 866/867. All types made in brass.

KLEEcoil for stamping and riveting

KLEEcoil tool

KLEEcoil tool for mounting various types of KLEEcoils. Makes work on larger tasks easier.

Thread coating

Brd. Klee can help with surface coating of screws and bolt products that need to be secured against detachment. Surface treatment of e.g. thread, screws, bolts, nuts can secure your application with:

- Extra thread fastening

- Provision of a fluid or gas-tight seal

- Protection against damage to the workpiece surface during screwing

- Extra protection against thread causing damage in e.g. thin plate

- Exactly dosed amount of surface treatment to avoid spills and tubes running etc

In collaboration with our manufacturer of Klee-coil we offer the following types of coating:

TufLok® blue nylon coating. For locking and sealing screw connections. Temperature from -56°C to +120° C.

Nytemp® orange nylon coating. Screw locking and sealing system for high temperature stress. Temperature up to +200° C.

Nyseal® Application of elastic seals on e.g. screws, either directly under the head, flange or on the thread run-out. Can eliminate the need for use of washers, seals or O-rings.

Nyplas® PVC/Plastisol sealing material, applied directly under the head, flange or runout threads on threaded elements. Can eliminate the need for use of washers, seals or O-rings.

Nycote® coating method involving the application of insulation teflon powder. The result is a protective layer which prevents unwanted deposits from primers, paints and other surfaces during the electrodeposition process.

Precote® locking coat for external and internal threads. Available in various executions. Temperature resistance by type up til +850° C.

Need help?

If you do not find the right KLEEcoil here on these pages or if you need guidance, then you are welcome to contact us. You can also see our KLEEcoil catalogue here.