Information about cable chains

Cable chain, energy chain, e-chain, cable drag chain. The product has many names. Here we use the term: Cable chains. We sell cable chains from CP System (CPS), which is a Korean manufacturer that produces high-quality cable chains.

Quality

CPS is certified according to ISO9001 and ISO14001 and supplies CE-marked and ATEX-approved (Ex) chains. All CPS chains are made of newly produced CPS-Amide (PA6+G.F) – Glass fiber reinforced Polyamide. The material has high impact strength and can withstand temperatures from – 30°C to + 130°C.

What is a cable chain?

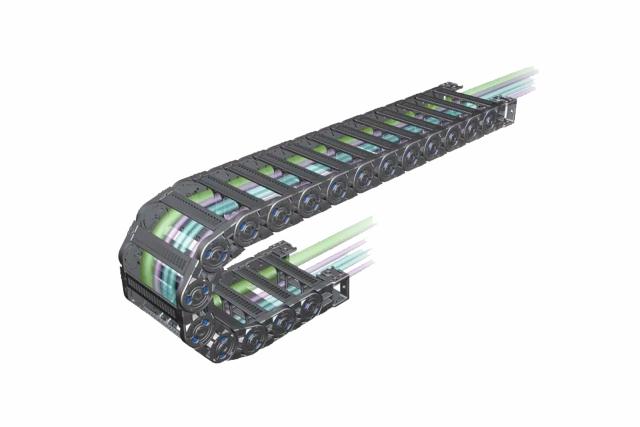

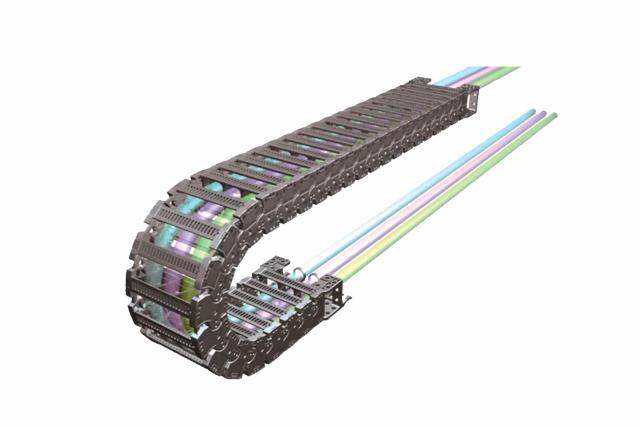

An cable chain is in most cases a plastic product (also available in steel) which is used to protect cables, hoses etc. in motion. The cable chain consists of parts that form a frame around the cables, thereby protecting them from external impacts and guiding the cables in the desired movement.

How is an cable chain used?

First, a chain with the correct dimensions is selected. The energy chain is then mounted on, for example, a machine. One end of the chain is mounted on the stationary part and the other is mounted on the moving part. The cables are placed in the energy chain (this can also be done before the assembly of the chain). When the moving part in the machine is in motion, the chain will guide cables in the desired movement.

Which cable chain should you choose?

This depends on your wishes:

- How much space is available?

- What are the dimensions of the cables?

- Which degree of bend is there room or need for? (flexibility of the cables)

- The length of the movement?

Accessories

We offer various accessories. E.g. guide systems for controlling and supporting the chains, as well as plastic tubes for protecting cables and accessories for robot arms (Roboway and Robo-Kit series).

Types of chains

The CPS range extends from small Mini Chains to Shift Chain (ST) and Sabin Chain (NSB), which are available in both open and closed, sliding and rolling chains.

Mini Chain

The Mini Chain/CPS Mini Chain is a simple chain offered in sizes from internal height from 10 mm and internal width 6 mm up to internal height 23 mm and internal width 77 mm.

The mini chain consists of links where the sides are connected with the lower frame. The upper frame can be removed from the chain when the cables need to be installed. This makes the cables easily accessable to the user. The radius is built into the sides and cannot be replaced.

In addition to the regular Mini chain CPS also offers a sliding type CPS48S. Sliding types are ideal for longer distances, as the chain folds on itself and thus does not need support from underneath.

Shift Chain (ST)

The ST chain is a larger chain offered in sizes from internal height 26 mm and internal width 35 mm up to internal height 110 mm and internal width 600 mm.

The ST chain is made up of the following separate elements, which can be assembled and disassembled as needed:

Sides (determines height), frames (determines width) and radius (determines the bend).

This means that the parts can be reused if the need changes.

The ST chain is offered in six types, each with their own unique characteristics.

Open(N): The open chain makes it easy for the user to access the cables. The individual parts are easy to change. The chains are partially self-supporting. If the chain is installed horizontally, the chain must be supported from below.

Closed(E): The closed has the same properties as the open (N) chain. The frames of the closed chain overlap each other, with which the chain protects the cables as much as possible.

Skid (S): The skid type is an open sliding chain. The chain bends down and rides on top of itself. This makes it possible to guide the cables in a longer movement without the chain having to be supported from below. With the open chain, there is still easy access to the cables. The chain has mounted sliding feet on the side pieces, which means that the chain slides more easily.

Closed Skid (ES): The closed sliding chain has the characteristics of the open sliding (S) as well as the added protection of the closing frames.

Rolling (RS): The rolling chain is a sliding chain made for longer distances. Also called Roller chain. It bends down and rides on top of itself. This means that support from below is not required. The chain has mounted sliding feet. On the underside of the sliding feet is a roller, which means that the chain can move faster and with less friction.

Closed rolling (ERS): The closed rolling chain has the same characteristics as the open (RS), as well as the added protection of the closing frames.

We stock the open chain (N). The other types can be supplied by order.

Sabin Chain (NSB)

The NSB chain is designed so that the chain in motion makes less noise. To reduce the noise, the radius is built into the side pieces, and therefore you cannot change the radius.

NSB open (N): The open chain makes it easy to access the cables and individual parts are easy to replace. The chains are partially self-supporting. The chain must be supported from below if the chain is mounted horizontally. The special feature of the NSB chain is that it is quieter and produces less dust.

NSB closed (E): This chain used in external particle-exposed environments. The closed chain has overlapping frames that optimally protect cables and hoses.

NSB Cleanroom (CR): The clean type is manufactured in UHMW-PE material (molecular 6.7M).

NSB Sliding (S): NSB is a sliding chain used for longer distances and where fast operation/high speed is required.

Need help?

If you do not find the right energy chain on this page or if you need guidance, you are very welcome to contact us.